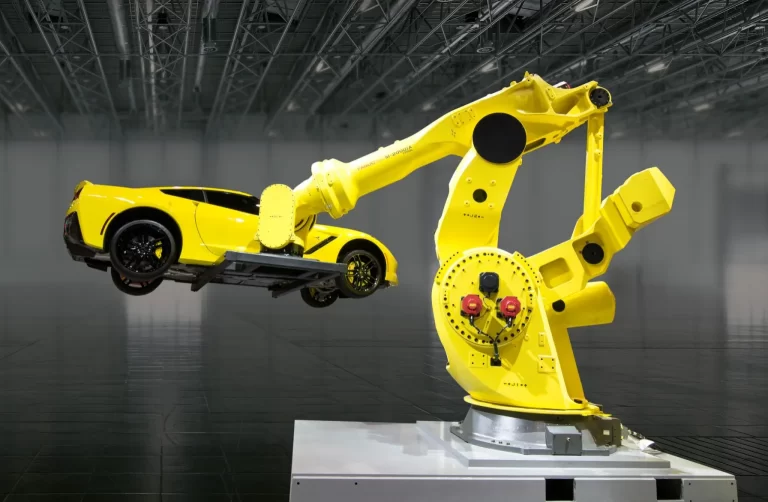

The development of robotic arms has revolutionized the manufacturing process, combining precision, safety, efficiency, and other elements that were previously impossible. These marvels of the mechanical realm – sometimes known as robot arms have been a necessity for industries around the world, motivated by the necessity to reduce operating costs without compromising on quality. Robotic arms are being incorporated into production lines to cut cost and increase security. We’ll investigate how these groundbreaking robots are changing the face of industry.

Image credit: automatedsolutions.com.au

The primary force behind the global surge in robotic arm adoption is cost efficiency. Factories are constantly under pressure to reduce manufacturing errors, cut down on material waste, and lower work-related accidents. Robotic arms are specifically designed to combat these challenges. In contrast to human workers, robotic arms perform repetitive tasks with pinpoint precision, eliminating costly mistakes and reducing waste of raw materials. For instance, in high-volume industries like automotive manufacturing, robotic arms execute precise welding and parts placement and ensure flawless assembly each time. This precision could translate into significant savings because less damaged products means less rework or waste.

Safety is another important aspect of the robotic arm revolution. Numerous manufacturing jobs like handling hazardous materials, or operating heavy machinery pose serious risks for human workers. Robot arms enable companies to get their workers out of dangerous work environments and prevent injuries in the workplace. Robotic arms are comprised of a number of movable joints that mimic the human arm’s function. They operate without any risk of injury. Equipped with programmable end effects basically robotic hands, the machines can be used for tasks like grabbing, spinning or welding under conditions that are hazardous for humans.

The range of applications for robot arms is an exciting development in a variety of industries. From automotive assembly to electronics production, robot arms can be adapted to a broad range of jobs. Their programmable nature allows them to perform intricate operations such as machine tool tending, painting, or fiberglass application with unmatched accuracy. Robotic arms in warehousing have revolutionized palletizing by automating loading of products onto pallets. Automation is not just efficient but also increases reliability since robot arms can operate without a lot of fatigue.

One of the most fascinating advancements in this field is the rising popularity of collaborative robots also known as cobots. These robots interact with human employees. Cobots, which are equipped with a robotic arm interact seamlessly with humans unlike industrial robots which are normally restricted to cells. Cobots equipped with robotic arms are able to perform routine or heavy lifting tasks in factories that allows humans to concentrate on more complex tasks. This type of collaboration boosts productivity while ensuring a safe work surroundings, as cobots can be programmed to stop or adjust their movement if someone is within the vicinity.

The effects of robotic arms go beyond safety and effectiveness to the very core of modern manufacturing. The ability of robotic arms to carry out tasks such as welding assembly, assembly, or even material handling with high accuracy is what makes them essential in high-stakes industries. Robot arms, for instance, can be utilized to move and rotate components during assembly in automotive industry, making sure that they are perfectly aligned with no human involvement. Robots are also utilized in electronics to manage delicate components. This helps reduce damage and enhances output quality.

As industries evolve, robotic arms’ role will grow. Since they can lower costs, increase safety, and change to meet the demands of different jobs they will become the foundations of future manufacturing. Combining cutting-edge technology with human ingenuity, robot arms are more than just tools. They’re partners who drive innovation, transforming how we build our world.